FactorySmart takes a different approach.

We optimise before we automate. Then we deliver smart manufacturing systems that transform how your factory works – step by step, with measurable results.

From precision tasks to proven outcomes

We don’t just sell machines. We power the core of modern manufacturing by bringing together machines and optimised process flow into one seamless solution.

Our work spans across key disciplines – ensuring that together, each precision task delivers the efficiency, consistency, and long-term performance you need from your factory floor.

Cutting

CNC Fibre laser, plasma, waterjet, oxyfuel, 2D/3D bevel cutting of flat sheets, profiles and tube with further options of drilling, tapping, milling and marking all on one machine.

Read more

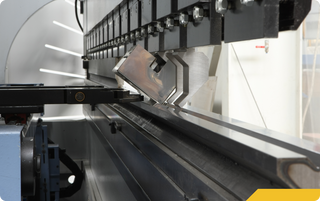

Bending and forming

CNC Pressbrakes, Robotic assisted bending, CNC Box and pan bending.

Laser welding

Handheld laser welding systems, Robotic, Cobot, and Motec assisted.

Optimisation

Layout design, process flow, lean improvements.

Support

Maintenance, upgrades, installations and fast local response.

World-class machines with local support.

We’re the trusted Sub-Saharan African partner for leading global manufacturing brands.

Our long-term partnerships give you access to top-tier technology – with the added benefit of local expertise and on-the-ground support.

Built on TRUST, CARE AND CREDIBILITY.

We’ve earned our reputation on the floor—not just on paper.

From machines to meaningful solutions

We began as the Sub-Saharan African agent for MicroStep – focused on cutting. But we grew with our clients’ needs. Today, FactorySmart offers a wide range of manufacturing solutions that combine best-in-class precision equipment with process expertise and ongoing support.

Our in-depth experience and personal commitment mean more value for you – from a partner who knows how to deliver, and who stays involved to support your success.

Products. Process. Partnership

What makes FactorySmart different isn’t just what we deliver, it’s how we deliver it.

Our tried and tested process makes all the difference – reducing risk, avoiding costly missteps, and getting the most out of your investment.

This is how we turn complexity into clarity – and potential into performance.

Take the next step toward a smarter factory

Let’s build a system that works better – together.

Don’t leave your next move to chance. Talk to our team and start building a future-fit factory today.